All-in-one Automated Clear Aligner Machine (film roll) HBL-YTJ-02

Specialized machine for dental invisible orthodontic industry. Mainly used for automatic processing and production of invisible aligners,offering high precison

Specialized machine for dental invisible orthodontic industry. Mainly used for automatic processing and production of invisible aligners,offering high precison, quality consistency, and full workflow automation from oral scanned data and film roll to finished aligners.It brings you smart and flexible manufacturing of complex,irregular and curved product,with high efficiency while not compromising on quality.

Special film feeder design,making it available for working with film rolls of different thickness,brands and widths.And after iterative upgrading,this working system is able to work with film width 105mm to meet the size of all aligners which should be manufactured by other equipment with the width 137mm on the market,reducing material cost by 20%.

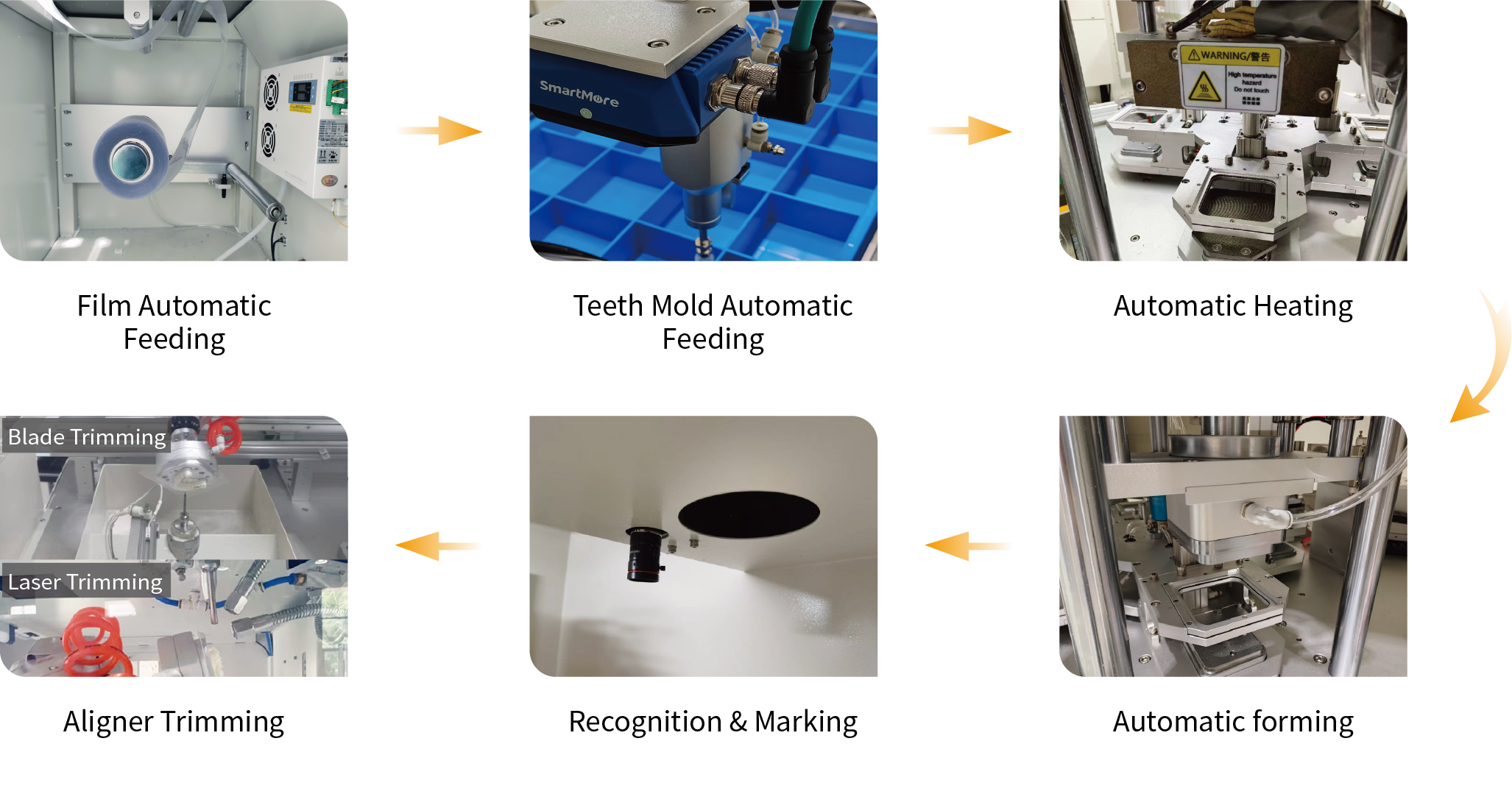

Workflow

Technical Features

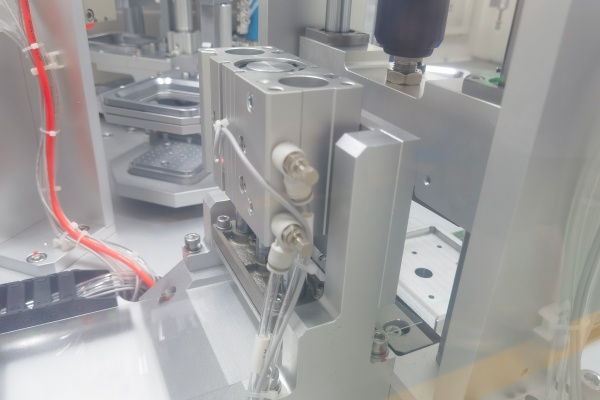

Automatic film cutting,full workflow automationUpdated working system with automatic film cutting module,a closed loop of full-workflow automation from film roll to finished aligners,reducing manual intervention. |

|

|

Automatic teeth mold feedingAvailable for visual recognizing and being precisely positioned on the machine tooling.Four boxes of teeth molds,running continuously for about one hour unattended. |

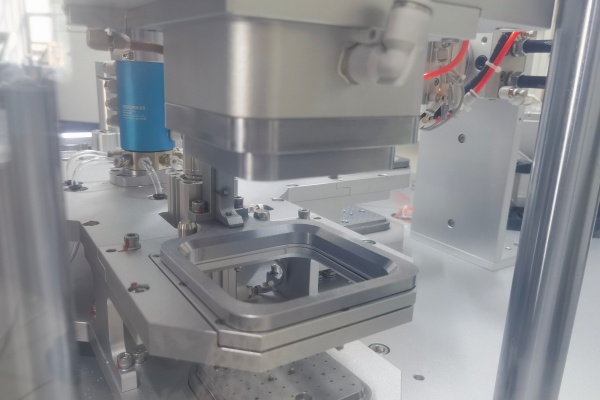

High fitting pressure thermoforming offeringFilm material evenly heated and softened,with the temperature 0-700℃ adjustable,creating a high fitting clear aligner prototype. |

|

|

Millimeter-level precision control for robotic trimmingThe high-precision ABB 6-axis robot provides high trimming quality consistency,millimeter-level synchronous control for flexible trimming of complex,irregular and curved aligners. |

Video Showcase

Technical Parameters

|

Film roll diameter |

≤450mm |

Teeth mold feeding |

4*24,96pcs |

|

Work efficiency |

30s/pcs |

Edge consistency |

<0.3mm |

|

Visual recognizing |

>98% |

Dimension |

2200*1200*2000mm |

|

Raw edge rate |

<2% |

Marking content |

number,letter,barcode,QR code,logo |

|

Cut defect rate |

<1% |

Film width |

100-137mm |

|

Marking content |

Number,letter,barcode,QR code,logo |

||

|

Function modules |

Automatic feeder,thermoform unit,laser marker,blade trimmer(or laser trimmer) |

||

|

Robot module |

ABB 6-axis;Arm span 703mm;weight 54kg,payload 7kg:power 0.39kw;repeated positioning accuracy 0.02mm |

||

|

Spindle module |

Power 800W;Rotational speed<40000r/min;Heat dissipation:Water cooling |

||

Machine Updates

|

Features |

First generation |

New generation |

|

Capacity |

90pcs/h |

120pcs/h |

|

Functions |

Thermoform,laser mark,blade trimming |

Thermoform,laser marker,(blade/laser)trimmer |

|

Feeder |

Teeth mold loaded by manual |

Automatic teeth feeder |

|

Application |

Film sheet (125mm round) |

film sheet(square or round) and film roll |

|

Dimension |

1650*1100*1900mm |

2200*1200*2000mm |

Reviews

There are no reviews yet.